The Key Difference Between Composite Window Systems

In general, aluminium-clad composite windows are the ultimate premium option for a long-term, low-maintenance and high performance window replacement. With a life expectancy of over 80 years and a U values below 0.8, it’s objectively the best possible material combination.

Not all composite windows are equal, and there are two very different methods of construction which could be very important to understand for your home.

To be clear, we’re not talking about the plastic-composite front doors you’ll see all over the UK – these are certainly not high-performance options!

Clip-On Aluminium-Cladding onto a Main Timber Frame

This is the simplest (and therefore cheapest) method of construction a composite window. There’s more to it than “take a timber window and stick a plate of aluminium to the front”, but that’s the easiest way of describing it!

A typical Danish timber frame is about 115mm in depth (front to back; inside to outside), making a few modifications to that frame allows clips to be positioned around the external face, to which the aluminium section is then attached onto. This method means that rainwater is able to drain through the gap in-between the timber and the aluminium – not a bad thing! The aluminium is still protecting the wood from the vast majority of weather and you shouldn’t need to perform any maintenance on the timber.

The important point that surrounds water being able to drain in-between the wood and the aluminium is, obviously, it needs to be able to drain out again. As you’d expect, the product is designed to do this, but there are a number of situations where external wall of a home can prevent this from happening and create some serious issues.

Render, EWI and Other Frame-Covering Details

If you have or are planning to have a external wall finish which, as a standard detail, is going to wrap around onto the face of the window, this creates the problem hinted at above. Rendering onto the window frame, or even just using a silicone seal around the front edge is going to block possible drainage routes from behind the aluminium. This traps rainwater up against the timber, which is going to introduce a huge risk of rot setting into the wood.

The most common red flags are:

- Render

- Timber Cladding

- External Wall Insulation (EWI Systems)

- Mastic or Silicone external seals

- Pointing or Cementing as the external seal

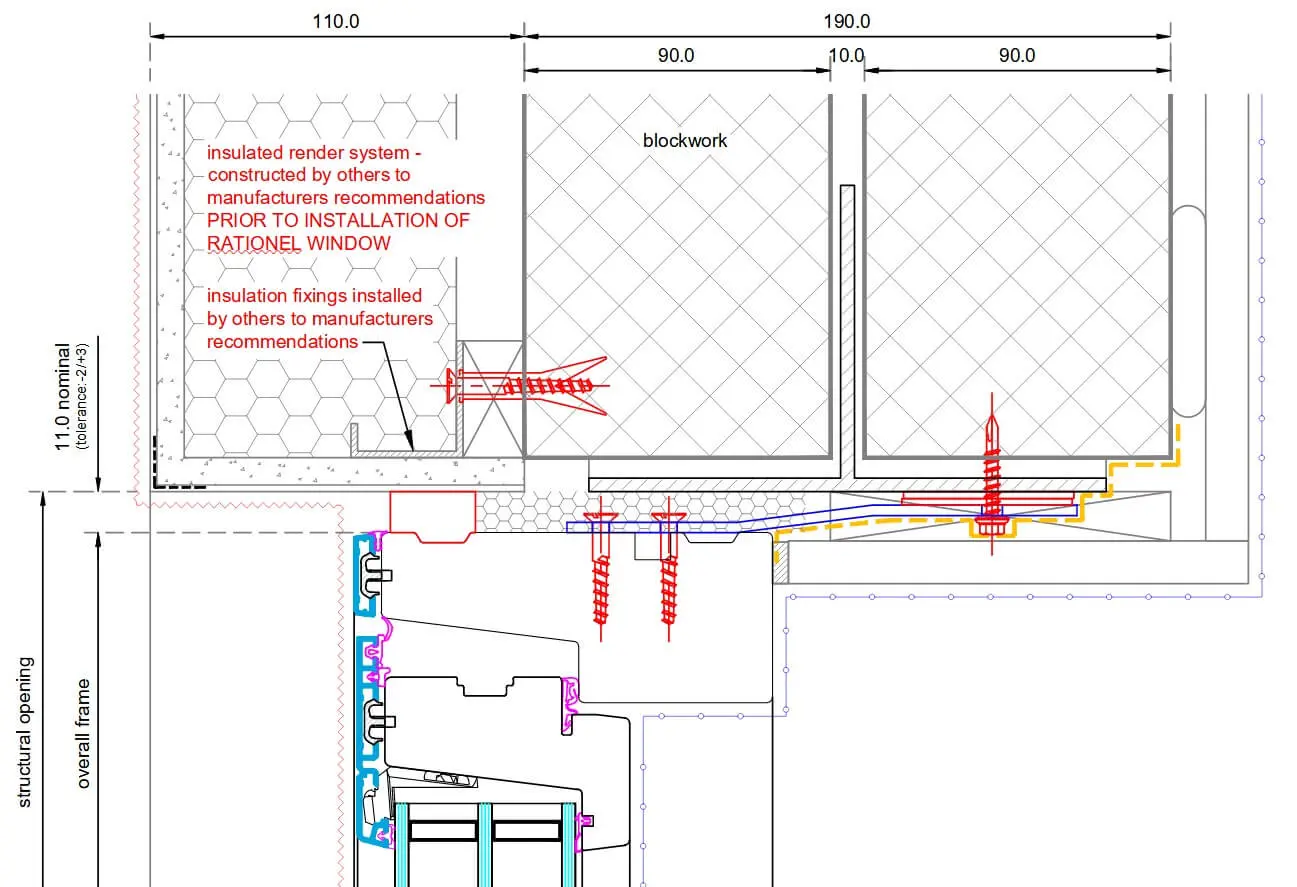

For render and timber cladding, there’s a really neat solution, which Rationel Windows in Denmark have created a few installation drawings for: the idea is that the render is applied way before the new window comes anywhere near the opening, and that render continues around the corner deep into the reveal. You then treat this slightly smaller opening as your new structural size, and that ensures that none of the drainage can be blocked.

This is actually a very good idea in general, because it means you’re not blocking the window in. So, if the window develops a fault and needs to be taken out, you don’t need to rip off the external wall covering.

Worth saying though, whilst this render-first method is absolutely perfect for newbuilds or renovations where the owners have moved out whilst the work is being done, it can be very awkward if you intend to live in the house whilst this is happening… If you replace a window with this method (focusing on render, but cladding and EWI is very similar), the order of work would be:

- If old render is on the building, this needs to be broken off to release the old windows

- Old windows removed

- New render is applied around the corner, into the reveal to create the new opening size

- Accurate measurements can now be taken for the new window (unless the renderer can guarantee their render thickness, then this step can happen a bit earlier)

- New window can be ordered, and that product’s leadtime now starts – potentially 2-3 months

- So…2-3 months will happen with boarded up windows before…

- New windows are finally installed

Since most people aren’t keen on waiting for a few months with a boarded up house, but would still like a composite window, the alternative window construction method is probably a better route to take…

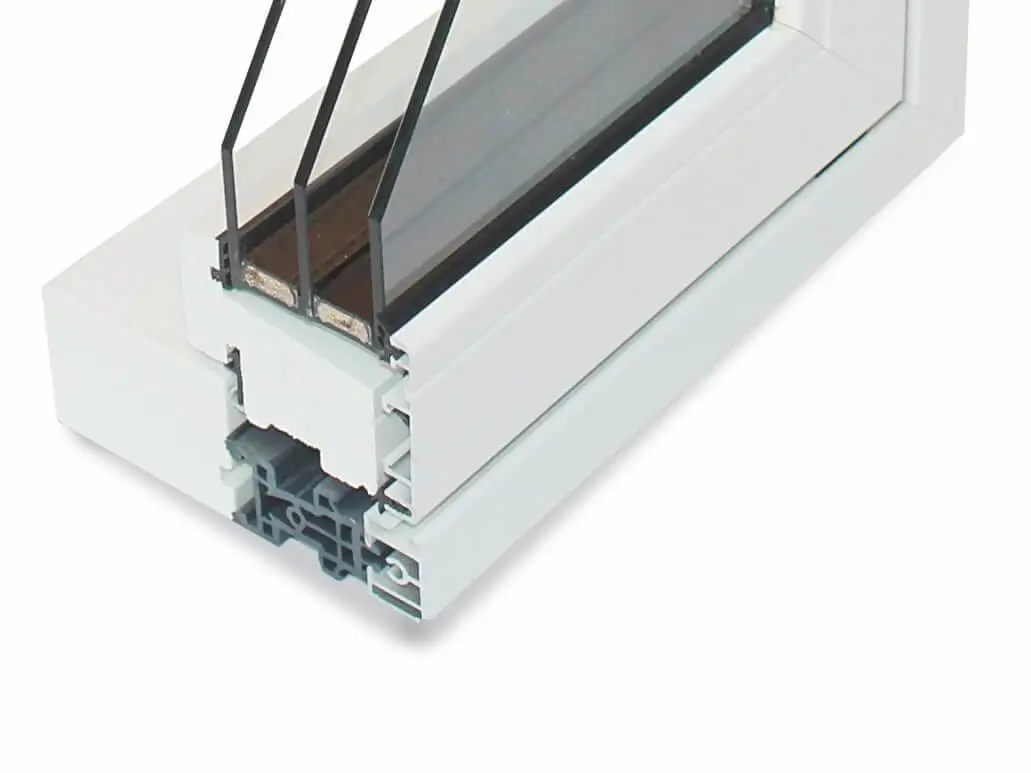

Complete Stand-Alone Design with Bonded Thermal Break

This is the best solution if you know that your external building finish is going to interfere with the window frame.

The timber interior section is fully separated by a polyamide thermal break, to which the external aluminium is that properly wrapped around. This means that rainwater cannot physically get to the timber, and its design allows you to treat it as though it were a purely timber or purely aluminium system.

(Almost) Any Installation Detail

Thanks to this more thought-out construction, you can do almost whatever you’d like when fixing and sealing the window in place. Rendering and cladding to the face is perfectly acceptable, as is mortaring up to the frame edge and pushing the window up to a check reveal from inside.

Do make sure to ask the supplier if there are any hidden drainage points in the system first though – even wrap-around systems sometimes require space underneath to allow any trapped rainwater to escape.

It’s also worth mentioning that, just because an install detail is possible, that doesn’t necessarily mean that it should be done. The majority of alu-clad timber composite windows have a strong focus on insulation. So, whilst it’s technically fine to seal up the outside with the same typical silicone sealant that you’d see on almost every UK plastic window, it’s really not a good idea to do so. The airtightness of a high performance window is completely ruined if a sub-standard sealing method is applied.

What to expect when replacing windows (without having to board them up)

Which is Better?

In terms of general quality, insulation and longevity, there’s no obvious rule to say whether either system is better or worse. Since the wrap-around option is a more complex manufacturing process, and involves an additional material, it’s highly likely that this will be a more expensive option. However, a lot of customers view it to be a worthwhile upgrade to avoid the headache of changing their intended installation detail to suit the simple clip-on system.

If you and your home are happy with the standard performance install of leaving a sensible gap around the window for an expanding foam and tape seal, there’s no reason to head in either direction. Choose the system you prefer based on how you view its quality and appearance.

But if any wet trade, EWI or cladding system is likely to be installed up against your new windows, choosing the wrap-around alu-clad timber composite window will solve a lot of headaches before they happen.

Our most popular wrap-around aluminium-clad timber window is STM Tinium:

We also have a number of client galleries featuring STM Tinium

For a more cost-effective option, the same Danish factory offer the STM NEO using the clip-on construction method.

We also offer a wrap-around aluminium-clad timber from Unik Funkis, available in double or triple glazing and uniquely-thin 19mm aluminium external glazing bars

We also have a number of client galleries featuring Unik Funkis

Contact us!

For any questions about our products and services, or to get your quote,

please get in touch by phone, email, or using our in-browser contact form!

Leamington: 01926 935 607

London: 0203 633 0476

E-mail : sales@enlightenedwindows.co.uk

Contact Form: Contact Us