- Why are Outward Opening Bifold Doors Better?

- Top-Hung Panels so that Multiple Seals are Compressed

- Why you shouldn’t have a Flush Threshold

- Thermal-Modification for Durability and Stability

- Ensuring Better Usability and Practicality

- Why don’t you offer an even number of panels?

- The Resulting Secure Ventilation Position

- From Our Perspective

For most people, the idea of airtight bifold doors is laughable. Most assume that bifolding doors have inherently poor insulation, change shape over time and tend to let in a fresh outside breeze whether you want them to or not. And, to be honest, this is still the case with some products. Luckily, our friends in Denmark were not only aware of the problem, but created a solution in the form of a airtight bifold from Lacuna. They also have a set of guidelines and rules to make sure that the bespoke product that you ask for will have class 4 airtightness and a U-value easily below 1.0 with triple glazing, no matter what size and how many panels you need.

So, in this article, we’ll not only explain how Lacuna themselves ensure that every bifold door they make is a class 4 airtight bifold door, but also (with a small amount of maths) explain why the factory refuse to make some less-effective configurations in order to provide customers with a better product.

More images from this project can be found in our Hampshire Major Home Renovation with Danish Windows gallery.

Why are Outward Opening Bifold Doors Better?

We think this is the easiest part of Lacuna’s philosophy to understand: wind is outside, not inside. That’s it!

When a strong breeze aims towards your closed bifold door, the force obviously pushes the doors in towards the house (rather than pulling them away). So, with an outward-opening door: the stronger the breeze, the more the doors will compress into the rubber seals. This enhances their ability to prevent drafts inside the home.

If the same door opened inwards: the stronger the breeze, the more the doors will be pushed away from the seals – reducing the effectiveness.

On a different note, it’s also worth considering the interior space you gain by letting the door open out.

Top-Hung Panels so that Multiple Seals are Compressed

One of the key differences between a Lacuna door and other bifolding options as that the door leaves hang from the top frame and slide around using a roller system. So all of the weight is taken by the lintel above the door frame.

The most obvious result of this is that there is no need to have a track cut out of the threshold. So there is nowhere for dirt and dust to collect and spoil the smoothness of the mechanism.

However, the arguably more important result of a top hung bifold is that the lack of track at the base does not restrict the doors from being properly compressed into the rubber seals. Better airtightness, watertightness and insulation in general all follow from this small detail. You may notice that there are actually two proper rubber seals in the threshold. This is far more effective than the single brush seal that many other products resort to.

Why you shouldn’t have a Flush Threshold

Perhaps the other easier area to understand is why it is better to have small steps in the threshold of an airtight bifold door, rather than have it completely flat.

If the threshold is flush and at the same level as exterior and interior floors, then there is nothing for a seal to compress against! Therefore, there must be a physical gap between the threshold and the panels, even when the doors are fully closed.

The normal “solution” to this is the use of a brush seal. By just looking at a brush, it’s clear this is nowhere near as effective as a proper rubber seal.

We think that the relatively small steps in Lacuna’s airtight bifold threshold over a very close-to-flush solution. And, paired with a complementary outside surface, can even be suitable for wheelchair users.

Thermal-Modification for Durability and Stability

The majority of problems bifold doors owner face a couple of years into their ownership is attributed to the quality of the frame material. Using a low grade of timber in small windows can be problematic, but using the same material in a large bifold door can be catastrophic. Assume that a softwood timber door expands by only 2mm per metre, this sounds okay. But multiply that across a 6 metre long bifold and, all of a sudden, it can’t be opened.

Lacuna use TMT Composite Heat-Treated Beech to great effect. This thermally-modified timber is baked at around 200 degrees centigrade, resulting in Class 1 (essentially permanent) durability. To test this, the founder of Lacuna was not merely content with a laboratory assessment. In addition, he lowered a bifold door panel in the local Danish harbour, left it for a few months and then pulled it out again. The result is truly outstanding. The CNC-machined grooves had not expanded at all. No swelling in the timber, really no changes other than it clearly needed a good clean.

Ensuring Better Usability and Practicality

Sliding an even number of panels together creates the inconvenient situation where you’re unable to open part of the bifold normally to step in and out.

Imagine a bifolding door with 2 panels. And you wish to open it. You can’t just open one panel because both must slide together, so what would you need to do? Locking points at both the side and the middle would need to be unhooked, and then both panels need to be slid across. But that means you’re not able to re-lock all the points when you’re on the other side of the door… And this is the same situation with any even number. We and Lacuna think this is not a practical solution.

The secret to always having a main traffic door built into the bifold is to always have an odd number of panels attached to each other. So a 4-leaf door would be split into 3+1. A 3-leaf door would have all 3 leaves sliding together. (And it’s much better to configure a 2-leaf bifold as a standard double door)

More images from this project can be found in our Traditional Cotswold Self-Build gallery.

Why don’t you offer an even number of panels?

You may think that the practical reason is all very well, but that doesn’t stop the factory from making them if you ask! Well, there’s another reason. And it relates to airtightness and insulation.

Bifold doors with an even number of panels attached and sliding together cannot have good airtightness.

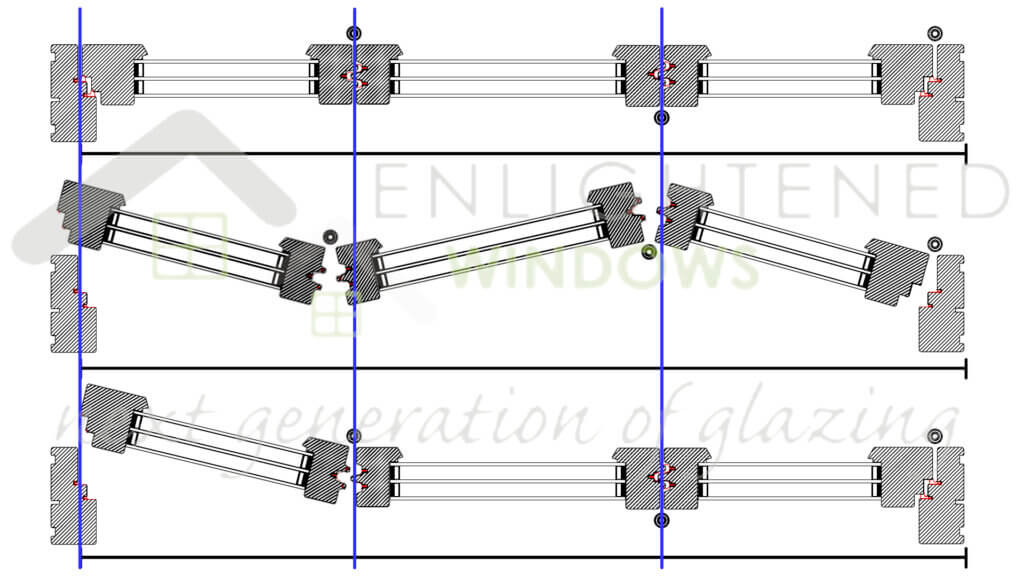

When you look at 2-leaves travelling together: to begin with, they obviously fit within the outer frame. But, because the hinges pivot point is outboard of the frame, the overall length of 2 doors together actually gets wider before they stack together. This is essentially trigonometry – hopefully the diagram above illustrates this better than a maths lesson.

But what does this mean? In a 2-leaf bifold, since the 2 doors must become wider after you start to open them, then either: 1. The panels would hit the outer frame as you open them. Or 2. To allow room to open, the panels are not compressed against a seal when they’re closed – so you will lose heat and notice drafts.

Obviously, any number of even panels is just multiples of 2, so the same principle applies on all even numbers.

So, the solution? Use a combination of an odd number of panels. Then, there is always space for this extra length increase without compromising on airtightness.

For more information about the configuration options available with our Lacuna Bi-folds please see our Lacuna Configurations and Accessories information.

The Resulting Secure Ventilation Position

A convenient side-effect of this slightly unintuitive property (of the doors spanning a larger width as you open them), it’s possible to lock the Lacuna bifold with a couple of panels pushed outwards from the frame. It’s impossible for the doors to open further or close for this position – again, thanks to the width-span property.

This gives a great solution when you’d like a small amount of airflow, but don’t want to leave a whole door open.

Although this is clearly not quite as secure as if the door were closed properly, only two locking points are not engaged in this position. So, even in the smallest-possible 3-leaf door, 5 bolts are still engaged.

From Our Perspective

“Actions speak louder than words” is a popular saying. And we are lucky enough that we are not constrained by any manufacturer to sell only their products. We are in the fantastic position to offer multiple choices for almost all of our product categories and materials.

But, we only offer one bifolding door. We use Lacuna bifold doors in our office, and we haven’t installed any other bifold into a customer’s home either. Lacuna are using next-generation materials on a tried and tested product that we believe cannot be matched in terms of the quality of both the bifold itself and the customer experience.

Most factories put their product in their showroom. Lacuna made their showroom from their airtight bifold door product.

Contact us!

For any questions about our products and services, or to get your quote,

please get in touch by phone, email, or using our in-browser contact form!

Leamington: 01926 935 607

London: 0203 633 0476

E-mail : sales@enlightenedwindows.co.uk

Contact Form: Contact Us