You may be self building, replacing existing windows, or you could be a builder with a client who needs some help. Either way, this article offers a summary of the main contenders; offering unbiased fact-based and informed recommendations.

The most popular windows that we’re asked for are composite (alu-clad timber), timber-only and plastic.

The Quick Answer

uPVC

- Low cost

- Low maintenance

- Low-mid range life expectancy

- Poor for the environment

- Large price increase for any colour other than white

- Short Lead Times

Timber

- Mid-range cost

- Regular maintenance recommended

- Mid-high range life expectancy

- Sustainable materials

- Selection of RAL colours available for the same cost

- Lead time around 8-10 weeks

Composite (alu-timber)

- Mid-high cost

- Low maintenance

- Very long life expectancy

- Sustainable materials

- Different colour inside and out at no extra cost

- Lead time around 8-10 weeks

Read on for further information, or give us a call on 01608 684 607 if you have a specific question!

1. Plastic, PVC and uPVC – In general, the most popular windows

The most popular windows sold in the UK are white PVC. This is mainly because they are the lowest cost option, they last 20-30 years on average and are often a like-for-like replacement for what is already in your home.

All in all, uPVC windows are

- Low cost

- Low maintenance

- Low-mid range life expectancy

Larger plastic units will require steel to be incorporated into the frames to give rigidity, but this also pushes up the cost.

However, we are seeing a decline. As people try to seek either a more attractive appearance (often with coloured frames), or a more environmentally-friendly product, other materials are required. Furthermore, PVC windows often don’t offer the best performance, unless in tilt and turn style with multiple seals between the sash and the frame.

What to Look For

Check that the seals are welded and continuous on the corners. If the seals are just roughly pushed together, then we recommend that you avoid: they won’t have the critical airtightness needed to achieve energy efficiency.

Often German-made uPVC windows are some of the best and offer a performance product, without poor recycled content (which quickly leads to yellowing of the plastic).

2. Wooden Windows – most popular windows in traditional areas

Wooden windows are definitely worth considering as they are sustainable, naturally insulating and also, if properly cared for, can last a very long time.

Timber windows come in either softwood or hardwood, and many of the options will be made from FSC timber (Forestry Stewardship Council). The FSC regulate of the source of the timber; ensuring that the source is managed in a sustainable manner. In older properties and more rural areas, the most popular windows do tend towards timber.

Ask your supplier what density is used to make their windows. Due to their high density, hardwoods and slow-grown pine have a natural propensity to absorb less moisture and humidity from the atmosphere.

In Germany, this is a commonly stated statistic in product marketing. But in the UK, it is rarely mentioned. Most manufacturers and re-sellers use a cheap lightweight timber which, on the face of the product, is difficult to spot. A softwood of above 450Kg per cubic metre is a dense slow grown product – resulting in a longer lifespan and less required maintenance. Hardwoods can be up to 650.

We offer some guidance to help you to really assess how high quality the timber is that you’re being sold.

Wood and Moisture

Generally, the denser the wood, the less likely it will absorb moisture.

Most timber windows will absorb some moisture whether new or old – this is normal and not a problem. This is how the windows are designed, as the timber is a living material and, even once made into a window, will continue to breathe. Thus keeping a harmony with the humidity of the outside environment.

When timber windows absorb moisture, a few things happen:

- 1. A slight expansion of the timber, meaning the sash can stick in the frame. This is particularly an issue on larger units: a 0.3% expansion on a 1200mm wide unit can represent a 3.6mm expansion of the frame.

A window frame with a lower density will expand more and be more prone to sticking.

- 2. Modern paint finishes are often made from microporous paints; allowing moisture trapped in the wood to escape. This is a good feature. Non-microporous paints won’t let moisture out. And, when moisture finds its way into the window, then the only way out is for the paint to be blister. Non-microporous paints should be avoided.

- 3. Water in timber + warmth = Fungal decay and onset of rot.

Usually the first signs are blistered paint and the softening of the timber. Once set in, this can be very difficult and expensive to repair.

- 4. Excessive moisture in the frame can also cause the sealed double or triple glazing units to rupture. You may see misting of the units or condensation in the panes. This usually means that the insulating gas in the glass is long gone and the window glass has failed.

It can be possible to replace the pane of glass, but often replacement is a short term cure – the real issue is the moisture in a deteriorated frame.

When a paint finish is in good order, then the above problems can be avoided. But, as paint ages with UV light from the sun, repetitive heating in the heat of the sun and also the harsh winter, then paint finishes may need attention.

A cracked or broken paint finish can allow driven rain to come direct into contact with the bare surface of timber thus allowing the water to penetrate the timber surface.

What to look for

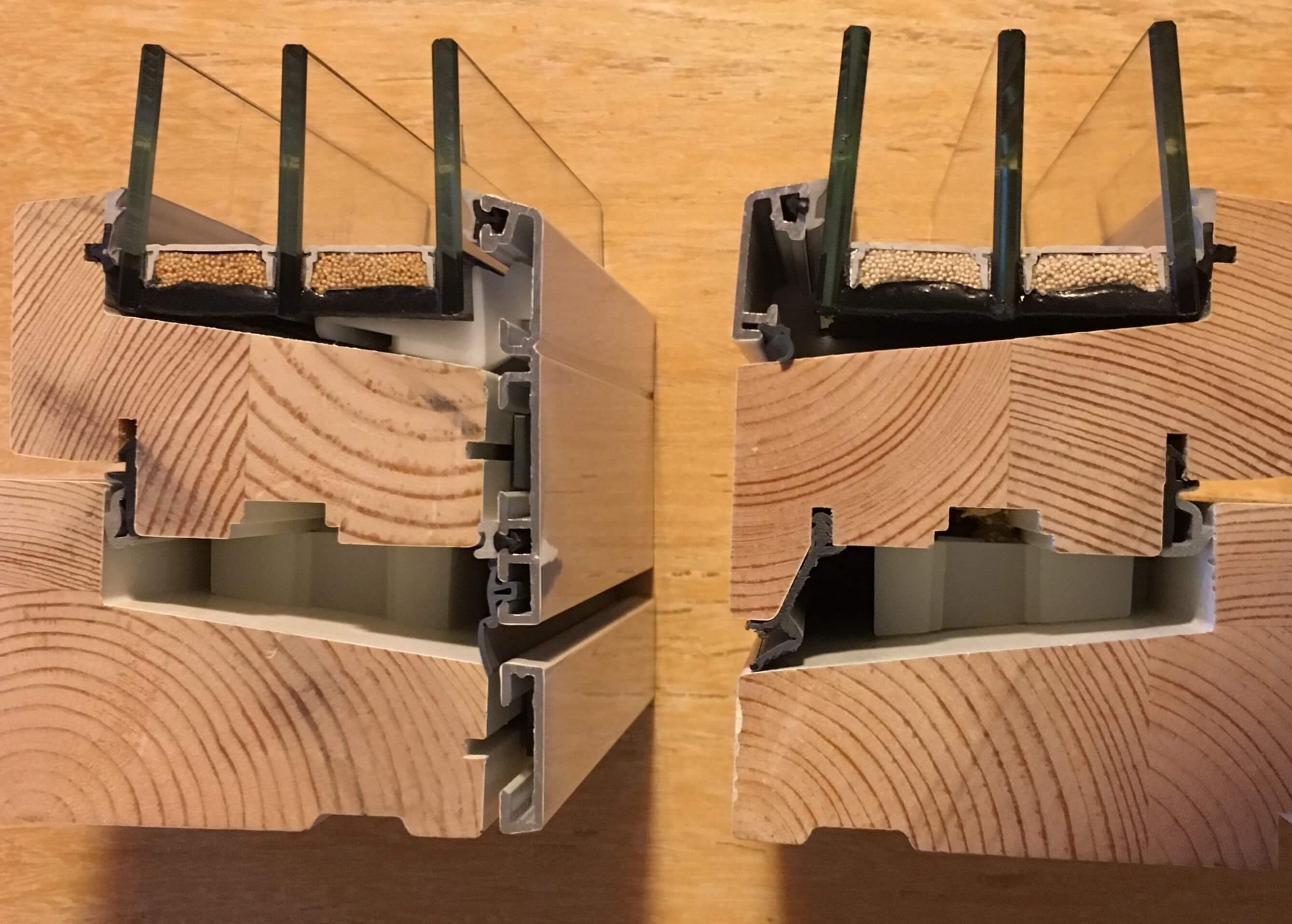

- Multiple seals made from butyl rubber

- Check seals are welded and continuous on the corners (mitres). If the seals are just roughly pushed together then avoid. They won’t have the all-critical airtightness that is the buzzword in achieving energy efficiency.

- Dense softwood ask for over 350Kg m3 as a minimum

- Microporous paints

- Engineered wood (rather than a window made from one solid timber piece of grown timber)

- Quality hardware and hinges. The typical hinges used on many cheap windows won’t tightly pull the sash into the frame and they themselves can cause water within the frame; accelerating deterioration.

- Quality workmanship, particularly on the joints of the window. Visible timber end grain is REALLY bad news. Even if it is painted, if this gets wet, it is the most likely place that water will be absorbed into the window frame.

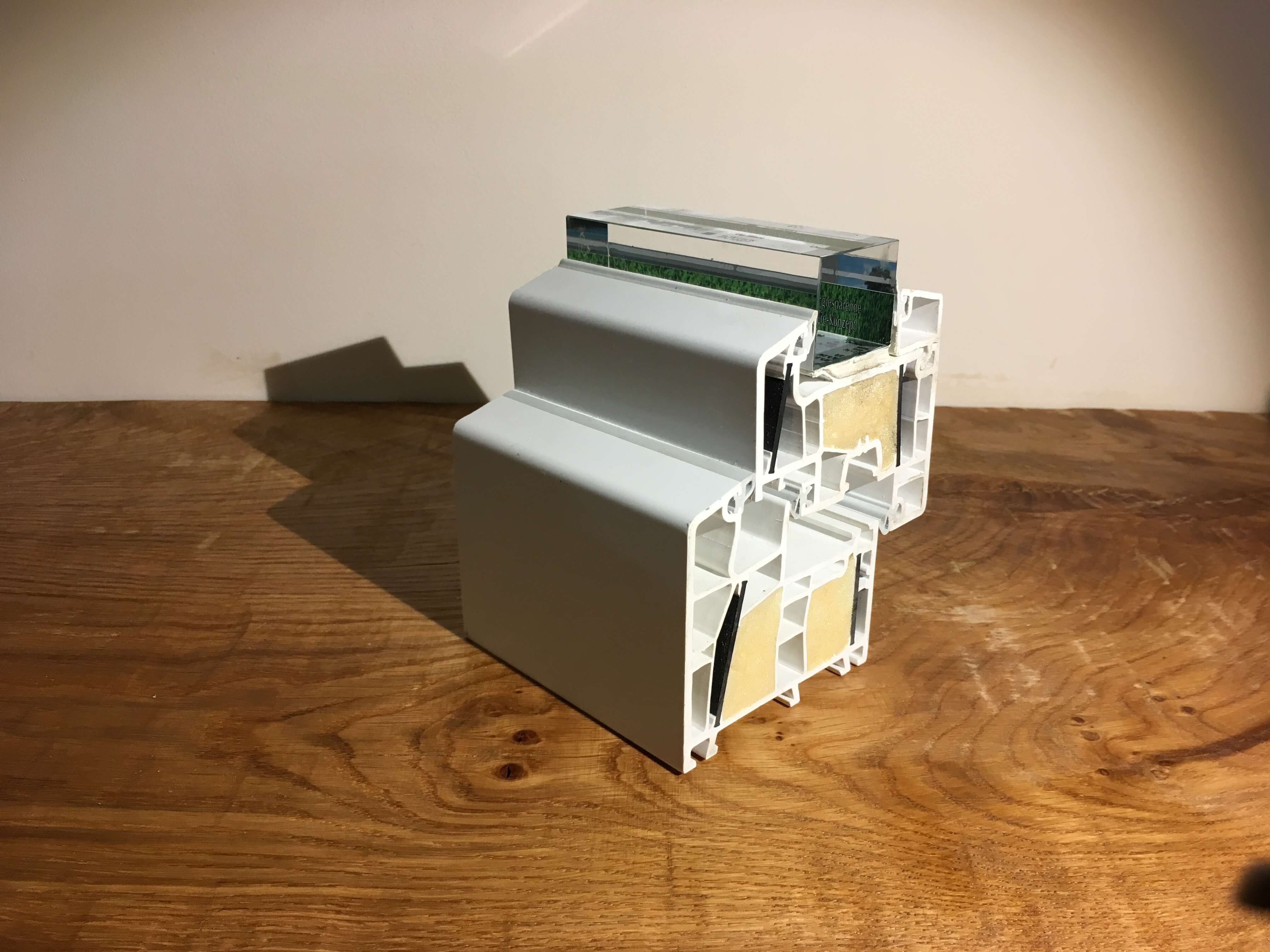

3. Composite Aluminium-Clad Timber Windows – the most popular windows we sell

If you’ve just read through the wooden windows section above, you already know the majority of information for composite windows.

The only difference between a timber-only window and an aluminium-clad timber composite window is a thin plate of aluminium on the external face.

This removes the maintenance issue with timber-only frames. For us, the most popular windows we sell are aluminium-timber composite.

Also, aluminium cladding adds the option of having a different colour inside and outside, normally without an additional cost.

As these are our most popular windows, we go into lots of detail in our composite windows article, but the main benefit is that the external timber is protected and now maintenance-free.

In addition to the items in the wooden windows section, be sure to ask if the aluminium is suitable for marine environments if you live near the coast. This is very important, as the salt and exposure to driving rain can deteriorate the powder-coat finish.

Contact us!

For any questions about our products and services, or to get your quote,

please get in touch by phone, email, or using our in-browser contact form!

Leamington: 01926 935 607

London: 0203 633 0476

E-mail : sales@enlightenedwindows.co.uk

Contact Form: Contact Us