Danish Window Manufacturing Quality

The cliche of most UK-made windows being poor quality with a focus on cheap and white plastic is sadly not unfounded. It is true that these windows still need to pass certain tests in order to be eligible to be installed into a UK home, but this box-ticking exercise doesn’t necessary take into account the longevity and, ultimately, what the customer will experience from the product over time.

Denmark have their own set of Building Regulations and requirements, just the same as the UK and most other countries. However, for windows and doors, more than 90% of Danish window manufacturing has one extra step that is rarely found anywhere else in the world.

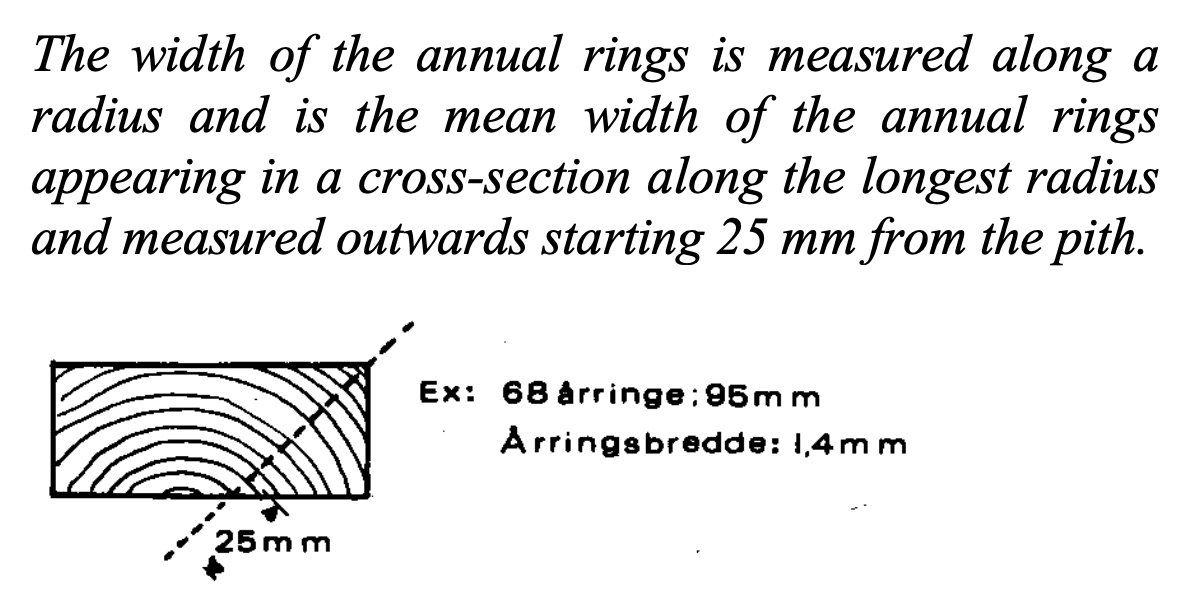

The Dansk Vindues Verifikation (“DVV” or “Danish Window Verification” in English) has the sole purpose of making sure that every window and door being produced in Denmark is made to the highest of standard. The DVV in its simplest form is a 165 page document that outlines everything that a window factory should achieve. For those factories who make DVV-marked products, everything is considered: from how the factory should structure their management and how the manufacturing plant should operate, to the moisture content and density of a timber window. Even the ring structure of the tree is outlined.

And, of course, this is all regularly inspected. Not just by the DVV (normally 2 full inspection visits per year), but each factory must select 5 random units every week and check against the DVV’s questions in the relevant material.

All this is obviously fantastic, and it means that the windows you buy are thoroughly inspected, but the extra customer-benefit is a warranty that not only comes from the manufacturer, but also the DVV itself.

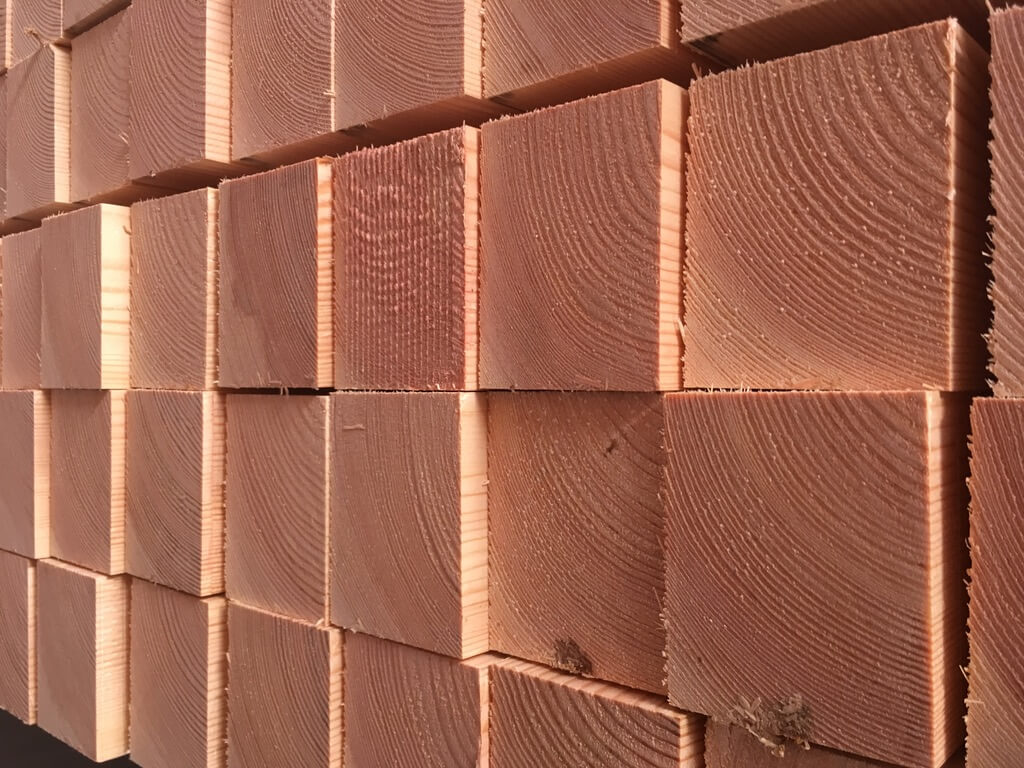

The Timber Itself

Here, we’ll be mostly talking about Nordic pine, as it is the most popular timber imported to the UK.

For pine, the mean density must be at least 500kg/m^3 when at a moisture content of 12%, and there are specific treatment systems that need to be used as a preservative, a base coat and the surface treatment. In storage, the moisture content of the timber must be maintained at 12% ± 3%. During production, this 12% must also be maintained, and it is checked every 2 hours.

In general, 3 sets of timber undergoes moisture stability testing once a week in the following cycle:

- at a water temperature of 20°C for 3 hours

- at a water temperature of 60° C for 3 hours

- at a water temperature of 20° C for 18 hours

- acclimatisation for 72 hours at 20° + 3° and 50 % ± 5 % relative humidity.

One of our Danish window manufacturers take this to the extreme and chooses to submerge their bifold door in a nearby harbour for 3 months at a time.

Tensile strength of Danish windows is also a weekly requirement on 5 test pieces, 60cm in length including a central finger joint.

The annual ring width must not exceed 4mm.

The size of a knot in the timber must not exceed (1 + 10 x L)/3, where L is the length of the timber. And knots that have technically been filled or plugged also count as knots in this requirement. To make things more simple, some Danish factories (STM for example) guarantee their timber to be knot-free.

Weather Tightness

For air permeability, a minimum of class 3 is required (class 4 for low-energy homes) when subjected to 600Pa (0.087 PSI) of both positive and negative pressure.

And class 8A for water tightness at 450Pa(0.065 PSI).

For both these tests, they are required to be evaluated in the actual use of the units, not just a set laboratory unit.

Burglary Prevention

I could write out a lot of test and certification numbers here, but the main classifications in Danish window manufacturing is EN1627-30.

And the summary is that general construction, hardware, glass and everything linking all those parts together must have sufficient resistance to attackers. Glass has security mastic to prevent it being removed.

In most cases, this certification is suitable for Part Q in the UK, as it has been judged to be “equivalent or better” than the UK PAS24 certification.

For further reading we have a full blog post about Buying Secure Windows and Doors.

Thermal Performance

There are two stages to this. In the UK, a manufacturer must provide one or the other. But in DK, they must provide both.

A standardised unit (1.23×1.48m) is provided for testing to determine values such as Uw, Gw, and LT.

U values are measured in Watts per meter kelvin

- Uw: The overall thermal performance of a window, a measurement of all parts of a window. This is based on the thickness and thermal conductivity of each part of the window.

- Ug: The thermal performance of the glazing in a window

- LT: Light transmission value, a percentage of the light that can pass through the glass

And, for every order, the performance data for every individual unit must be calculated. This is where UK-made products often simply provide the standardised values.

A factor that helps with this is the seals. Either rubber or rubber-like seals are a requirement, and brush seals (common in UK products) are only approved in special cases.

Thermal performance can be complicated, but for a synopsis we have our Window and Glass Insulation Data Explained blog.

The Aluminium Cladding

If you opt for aluminium-cladding on the exterior of a timber window, this aluminium must be free from oxide impurities, blisters, distortions or cracks. Essentially, there must be no unintentional marks.

Joints in aluminium must be flush, and the tolerance is 0.3mm – a typically small tolerance in Danish window manufacturing. Plus, where hinges are positioned, the profile thickness must be at least 1.8mm.

Our Key Difference Between Composite Window Systems blog goes into more detail about how the type of cladding can effect your choices.

Glass

Glass units are treated, for the most part, as separate components to the overall window. They must have their own testing certificates and warranty – essentially they must prove their own worth before being used in any window.

There are the somewhat obvious rules that say there should not be any visual defects or impurities. Toughened and laminated glass should not cause any distortion as you look through, and the units must remain stable when exposed to humidity.

All in all, we love the attention to detail, overall incredible care and pride that our Danish manufacturers and Danish window manufacturing as a whole has in their products. Whilst we are a British company, and would love to use solely British manufacturers, UK window manufacturing is years behind. The recent UK government grant highlights this: whilst the UK is pushing the removal of single glazing in favour of double, Denmark is aiming to only produce triple-glazing for new homes by the end of 2020.

Contact us!

For any questions about our products and services, or to get your quote,

please get in touch by phone, email, or using our in-browser contact form!

Leamington: 01926 935 607

London: 0203 633 0476

E-mail : sales@enlightenedwindows.co.uk

Contact Form: Contact Us