- Double or Triple Glazing

- Trickle Vents

- Traditional or Modern

- Timber Windows on New Build Properties

- Aluminium-Clad Timber Frames on New Build Windows

- Plastic and Aluminium

Self-building a brand new home yourself can be a daunting task, but we are self-build specialists and very used to guiding you through the process – ensuring you know the issues you need to consider. We have a collective 30 years of experience of working with self builders and have an intrinsic understanding of both the build process and modern building systems. When dealing with new build glazing, this additional knowledge is so essential.

We are a family-owned company with no investors or shareholder so you can be assured that we always provide best advice rather than selling but also a fantastic opportunity to create exactly what you want, with all the features and benefits you could ever need. Self Building is becoming more and more popular and having a company along side you to work with you advise on all of your glazing needs is essential.

Perhaps the best way to start off is to attend one of the many exhibitions throughout the country specifically for people undertaking new build projects. Events, such as the Build It shows or the National Self Build and Renovation Centre ( still open despite covid), will have a number of different suppliers who you can talk to about your build, ask for advice and help you decide how to progress. There are often short presentations throughout the day that cover specific areas of interest. For windows and doors especially, you can be sure to find a diverse range of materials, countries of origin, design aesthetics and opening mechanisms.

Here is a selection of the choices for new build windows and doors you’re sure to come across and what we would recommend:

Double or Triple Glazing

This is where you can get ahead of the schedule should you wish to. At the time of writing, the UK government are working on an incentive scheme to encourage people away from single glazing to double. Meanwhile, Building Regulations in Denmark are being re-written to make triple glazing a requirement. We have a whole article on just how far ahead Scandinavian countries are when it comes to window manufacturing in Denmark if you’re interested.

For new build homes, unless you know that the rest of your chosen materials won’t complement the choice, we recommend triple glazing. Better insulation, better airtightness and better sound reduction make it a much more long-term choice. Pairing triple glazed windows with a mechanical heat recovery system gives you a solid base for having a cold-in-summer, warm-in-winter home.

Trickle Vents

Having briefly mentioned mechanical heat recovery, trickle vents are an alternative method of providing background ventilation. Trickle vents are literally a hole cut through the window frame with a cover you can open or close. For somewhat obvious reasons, more high-end manufacturers don’t recommend this method in their class 4 airtight triple glazed options. That’s not to say you shouldn’t, more of a note saying that including those vents undoes an amount of work, so you perhaps won’t feel the full benefit of triple glazing.

If trickle vents are a must-have for a customer, we normally ask whether or not they mind seeing a “hood vent” on the outside. The two windows in the photos below both have trickle vents, but one is clearly more obvious. You may find that you are the sort of person who doesn’t mind this sort of design feature, which does open up both design options and cost-saving options further. But many prefer to hide vents wherever possible.

Traditional or Modern

As you can probably guess, this is a rather flexible area. Regardless of the insulation level you require, traditional-looking new build windows are still made to the same modern requirements as ultra-modern products. So there’s no need to buy the most modern-looking window to get good energy-efficiency.

Modern windows can still look perfectly at home in traditional projects – adding more intricate details to an otherwise minimalist view. And traditional windows can give modern projects a bit more character. We suggest that you’re just a little cautious when designing in decorative glazing bars.

Solutions for new build windows nowadays no-longer impact airtightness, but they can heavily impact the price.

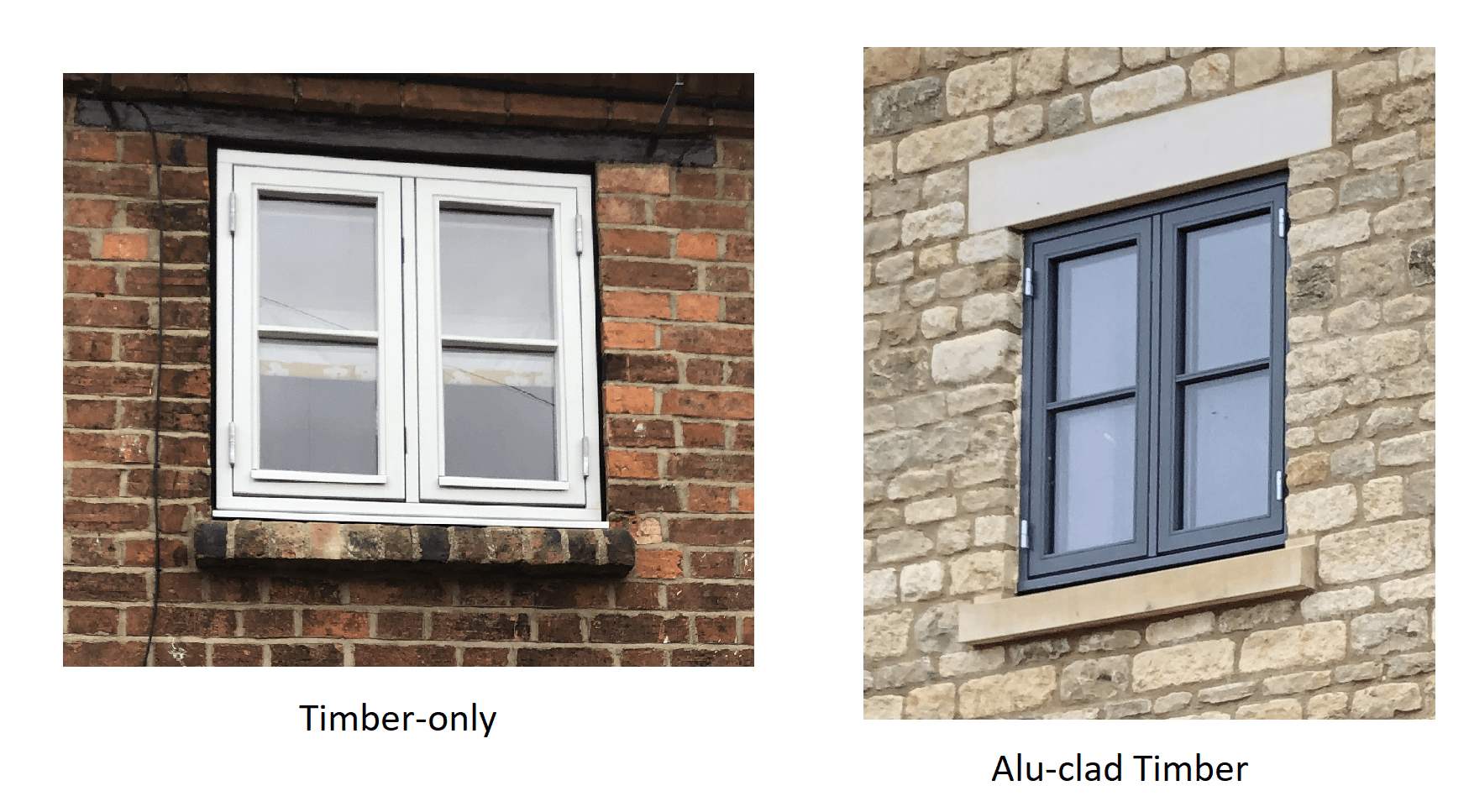

Timber Windows on New Build Properties

Your first thought is probably along the lines of whether you need to repaint the timber window frames every so often. And simply put, yes. To keep a timber window looking and performing good-as-new, they should be maintained (on average) every 5 years. We completely understand this isn’t for everyone. However, the benefits may outweigh this for you. Especially when you consider that a well-maintained wooden window can have a life-span of 50+ years.

For energy-efficient homes, engineered, finger-jointed and, if possible, heartwood timber is a fantastic place to start. The material is naturally highly-insulating and timber interiors in-general provide a lovely and warm feeling inside a home.

To make sure you are buying high quality, make sure that you know the timber density and that the windows are finished with a water-based paint. Even our softwood pine windows have a density between 470-500kg/m^3. And water-based paints are essential for preventing trapped moisture within the timber: oiled-based paints should be avoided at all costs. We recommend that you look for a knot-free guarantee too because, whilst not a certainty, even small knots can bleed through paint.

Aluminium-Clad Timber Frames on New Build Windows

If the thought of maintaining timber windows throughout their long life firmly discourages you, do not worry. You’re not alone!

Composite (alu-clad timber) windows were created for this exact reason. And, with this option, you are able to experience the benefits of a timber window without the drawbacks. These windows provide your new build project with arguably the best possible option: low to zero maintenance, potentially Passivhaus levels of insulation and a lifespan happily over 80 years.

Somewhat unsurprisingly, these advantages do come at a cost. You’ll often find that alu-clad timber windows cost a noticeable amount more than any other option, and it’s really a consideration for you to decide if this long-term, eco-friendly investment is worth the cost for you personally.

We have a quick guide to composite windows in another article

Plastic and Aluminium

Although clearly very different materials, we are discussing these together because, for us, they end in the same conclusion. We do not recommend uPVC or aluminium-only windows for new build windows.

uPVC is quite simple to explain: the manufacturing process is incredibly damaging to the environment, without providing a noticeable benefit to customers. Plastic windows generate 43% more waste than timber. Of which, 83% goes to landfill, 15% is incinerated (releasing hazardous chemicals) and only 3% is recycled. 43% of a brand new plastic window is composed of ethylene – this is a new-renewable resource. (statistics from wwf.org.uk)

The table below outlines that you, the buyer, don’t even benefit from this over time.

The whole life cost over 60 years for a typical 1.5m2 window

| Timber | PVC | |

| Expected life | 60 years | 20 years |

| Renewal Cost | £500 | £420 |

| Renewal cost over 60 years | £0 | £840 |

| Maintenance cost over 60 years | £787 | £460 |

| Whole life cost over 60 years | £1,287 | £1,720 |

| Whole life cost compared to PVCu | -25 per cent | 0 per cent |

The data for this table is based on: Thompson, C., 2005. Window Of Opportunity.

[ebook] WWF, p.12. Available at: WWF.org [Accessed 15 October 2020].

As a company, we believe that plastic windows should no longer be sold. When David Attenborough stood on stage at Glastonbury in 2019 declaring his views on plastic and the environment, we made a stance as a business to remove plastic windows from our portfolio. We realise these are always the cheapest option. but have poor longevity and performance. These units rarely last more than 3 to 5 years due to the oil-based seals designed-in by most manufacturers.

We have now removed all PVC windows from our ranges

Aluminium thankfully doesn’t have anywhere near this level of controversy behind it. It’s a sustainable resource that can be recycled and has a very long lifespan. However, aluminium-only windows generally give you a poor price-performance ratio. Aluminium as a material is naturally very good at conducting heat – not something you want from a window frame. Most manufacturers improve this by adding a thermal break, but it’s still very likely you’ll experience condensation forming on the inside of the metal frame. Plus, some aluminium products require triple glazing to be compliant with UK Building Regulations – not a good sign.

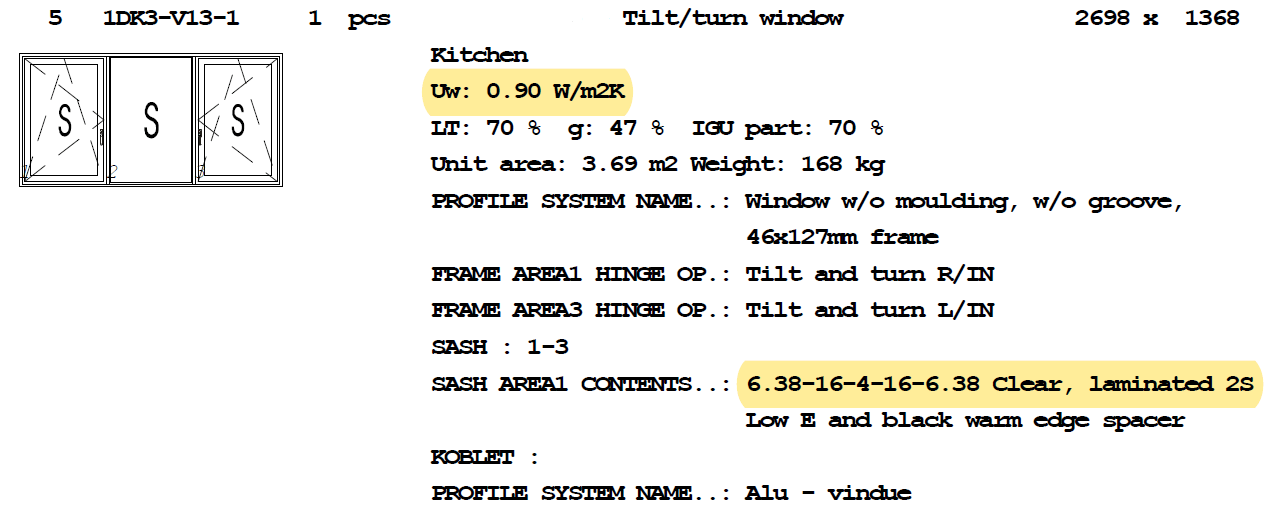

The U-values given for aluminium windows are often based on pre-set configuration (so not based on your actual order). We obtained some Uw value calculations for particular aluminium window, and we can say that this “standard configuration” value can be very far off the truth. A product with an advertised Uw = 1.5 W/m^2k actually had Uw values around the 2.5 mark, if you did the maths for the actual windows being quoted. For some context, our Danish timber windows tend to average around 0.9 for triple glazing and 1.4 for double. So 2.5 is quite a large step out.

Whilst aluminium is not our material of choice, sometimes – with particularly large units or where we are replacing steel crystal style windows – there is no other choice but to use aluminium as a material. To that end, we do still sell aluminium. But we sell it with a health-warning: condensation can be seen on the frames because they will always be the cold point in the room, even when thermally broken.

Often, aluminium can deliver significant improvement and offer a similar appearance to old steel window replacements. So, whilst these will not be the highest energy efficiency, they still can offer a noticeable improvement when no other choice exists.

Security, Part Q, and PAS 24 for New Build Windows

Security is a surprisingly awkward area in the UK because, whilst the rest of Europe have a set of tests that are recognised in all European countries, we have our own separate set of tests and certifications that only apply to UK homes. This puts European manufacturers in the situation where they could perform the European tests, and make their product suitable for all of Europe, or perform UK tests and be suitable for the UK only. Unsurprisingly, most choose the first option – meaning that a lot of fantastic high-end products initially don’t seem to be an option.

Luckily, there is a solution. Many local Building Control Officers are familiar with European security certifications: simply explain which certifications your window of choice has and, providing it is comparatively the same or better than PAS24 (the main UK certification), they should give you a positive answer.

In simple terms: for your windows to be secure according to UK Building Regulations, they must be compliant with Part Q. The main UK certification that shows this PAS24, and there are many European certifications that have proved to be equal or better.

Building Regulations for New Build Windows in General

Luckily for the self-builder, most other parts of UK Building Regulations are easy to keep track of. We won’t go into great detail, as this topic really deserves it’s own article.

As a minimum, for your new build windows and doors, your supplier should be able to provide evidence that the relevant windows comply with Part B for fire egress, Part F for different types of ventilation, Part K (mainly safety glass for windows in critical areas, but also restricted openings where needed), Part L (essentially U-values, insulation and energy conservation), and Part M for disabled access.

From us, after we know which rooms are bedrooms (fire escape), which windows are within 800mm of floor level or 300mm of a door (safety glass) and the final dimensions of the units: we will provide an overall Uw-value for each individual unit, let you know which windows are fire egress compliant (and help you re-configure windows if they aren’t), let you know the clear width of your front door for Part M, and all units that need safety will have a note displayed showing the type of safety glass we have quoted for – normally toughened and laminated.

Contact us!

For any questions about our products and services, or to get your quote,

please get in touch by phone, email, or using our in-browser contact form!

Leamington: 01926 935 607

London: 0203 633 0476

E-mail : sales@enlightenedwindows.co.uk

Contact Form: Contact Us